Because things always happen at 2am.

Fluke vibration monitoring.

With our wireless tools cloud storage mobile app and software you can start a preventive maintenance or.

As described previously an advanced vibration testing tool the fluke 810 vibration tester has a diagnostic engine that combines algorithms with a database of real world measurement experience.

Quickly understand the condition of each asset and determine what to prioritize.

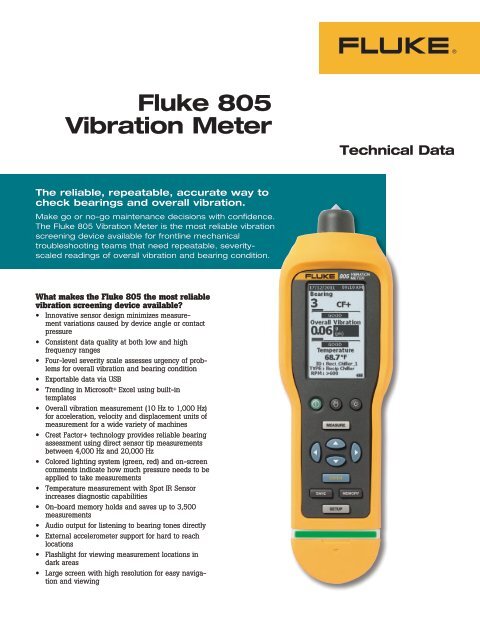

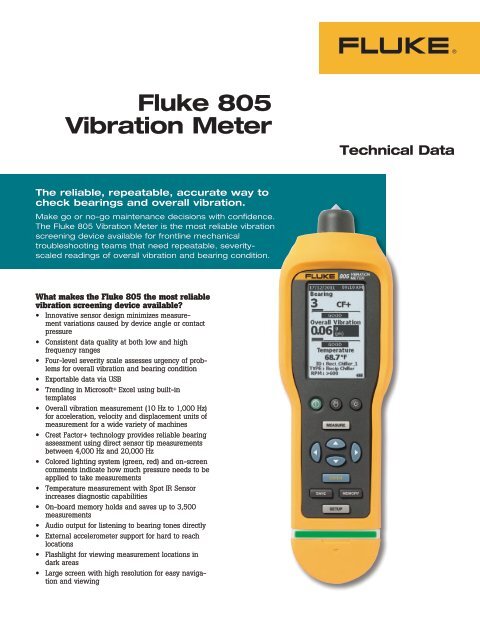

Fluke vibration testing and laser shaft alignment equipment and systems were designed specifically for maintenance professionals who need to quickly perform vibration analysis and evaluate alignment to understand the root cause of equipment condition.

Start your condition monitoring program today with the sensors and software from fluke connect.

Using the fluke connect condition monitoring fccm software with vibration sensors ensures that all data is organized and next step decisions can be made efficiently.

Get a quick snapshot of asset trends recent alarms and activities and the status of your fluke sensor.

Understanding the benefits of vibration monitoring and analysis pdf.

Use fccm software to wirelessly collect real time information seamlessly revisit historical trends and graph data for further analysis.

The fluke connect asset health dashboard provides a simple concise view of your facility s asset health.

Vibration monitoring devices use accelerometers to measure changes in amplitude frequency and intensity of forces that damage rotating equipment.

Minimize maintenance routes and extend asset life by observing triaxial measurements from fluke 3561 fc vibration sensors via fluke connect tm condition monitoring software.

While all machinery vibrates monitoring excess vibration in rotating equipment is key to early identification of asset issues.

Http bit ly 2rxfpfr in this video learn the 7 steps to install the easy fluke condition monitoring and how fluke condition monitoring can help strengthen.

Fluke connect is the best way to stay in contact with your team without leaving the field.

Vibration screening notifies users of changes in rotational forces that can damage equipment if left unchecked.