A laser beam that will be fired from the laser generator which is focused into a laser beam with high power density through the optical path system.

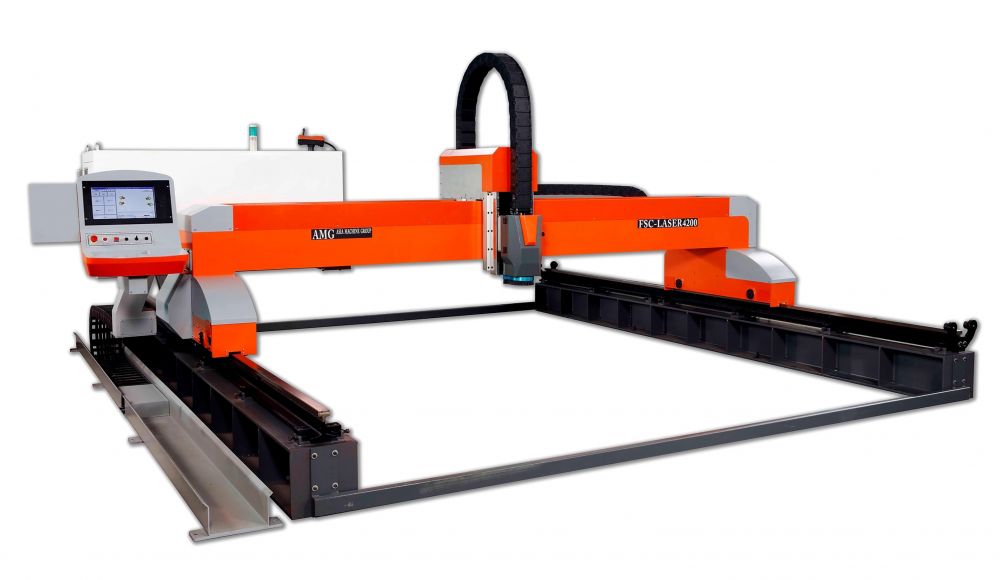

Fiber laser cutting machine specification.

4 0 kw or 6 0 kw ipg fiber laser power.

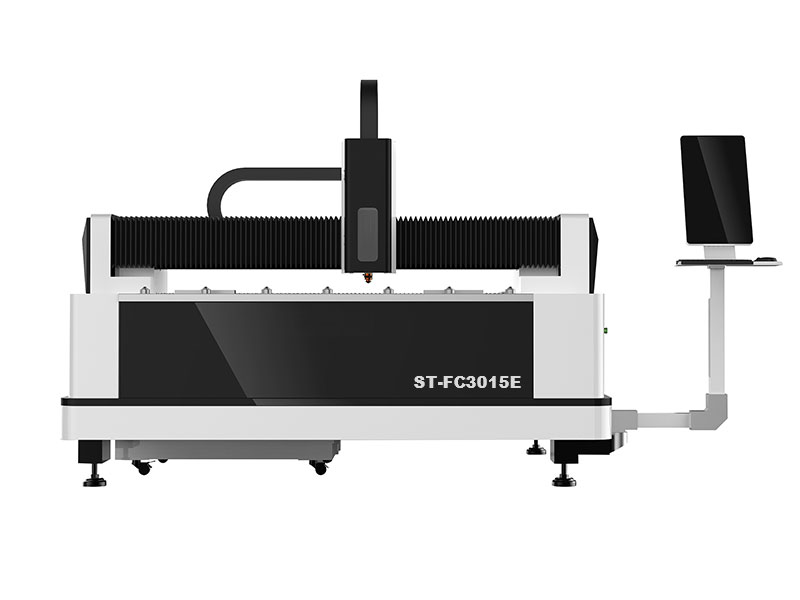

Also when processing stainless aluminum brass or copper materials fiber lasers are the fastest and most economical regardless of material thickness.

Accu 5 x10 fiber laser metal sheet cutting machine in stock from 1000 2000 w from.

The laser beam hits the surface of the workpiece so that the workpiece reaches the melting point or.

This technology helps achieve process range expansion p r e by having the ability to process brass copper and titanium materials that can be difficult to process with a co 2 laser.

Fiber laser cutting machine s 2020 05 05 01 41 high power fiber laser cutting machine nancy 2020 04 11 00 36 fiber laser cutting machine g 2019 12 24 03 41.

Fiber laser cutting process.

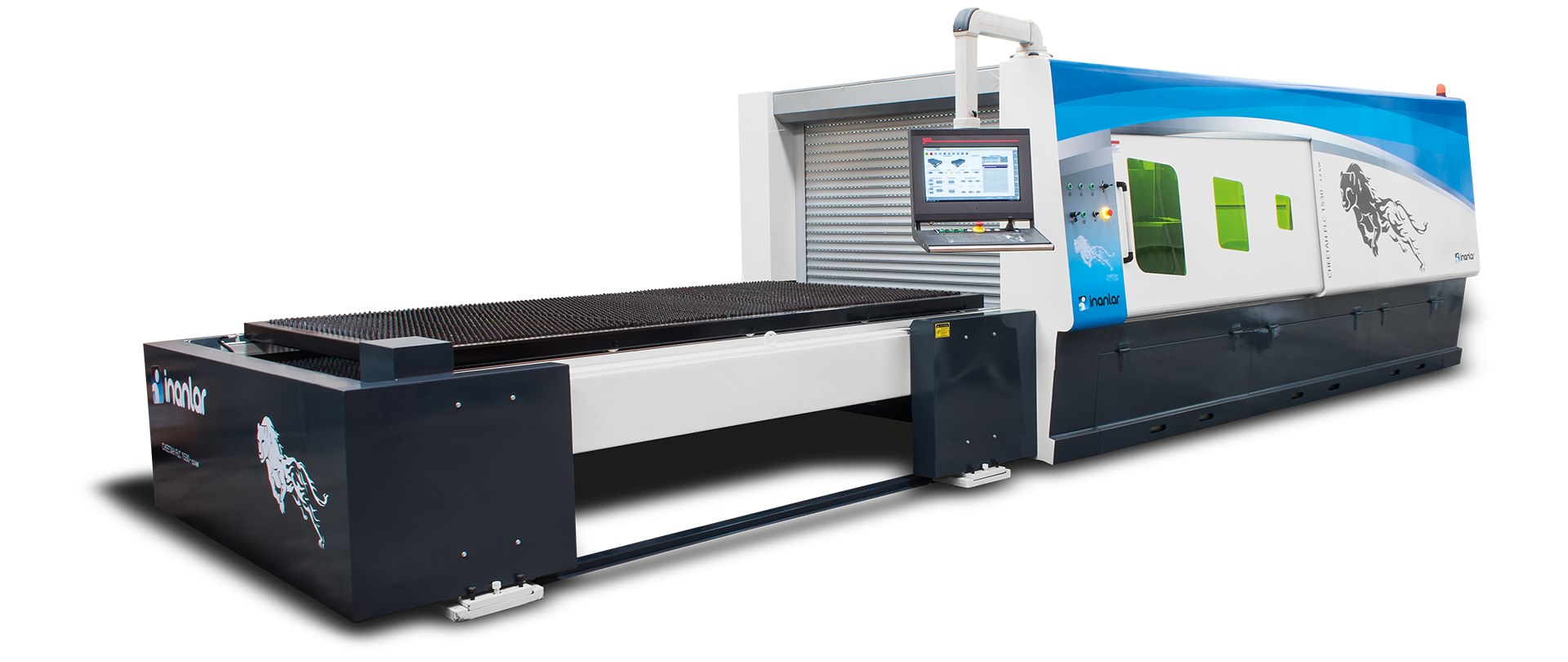

Han s laser independently developed various types of fiber laser cutting machines co2 laser cutting machines yag laser cutting machines and other series of products.

61 x 122 cutting area.

And how are works for fiber laser cutting machine.

Compared to conventional cutting methods laser cutting provides many advantages including.

This means that the raw sheet rests on the cutting table and the laser head moves in x and y directions.

75 000 00 75 000 00 97 000 00 97 000 00 compact 4 x4 fiber laser metal sheet cutting machine 500 3000 w.

Laser beams are a single point cutting source with a very small point 0 001 to 0 020 or 0 025 mm to 0 5 mm which allows very small cut widths.

Piranha laser m series m510 fiber laser cutting machines are workhorse machines designed to run a wide range of material types and thicknesses.

Fiber laser cutting machine.

The 3kw 6kw and 9kw lcg aj series was developed with amada s proven fiber laser technology.

Let s dive into it.

Mps 3015d f series fiber laser cutting machine hf series fiber laser cutting machine mps 3015c mps 3015dt.

The world s first laser cutting machine was born in the 1970s.

1 lens 2 the laser beam 3 airflow 4 the line 5 molten material 6 cutting surface 7 nozzle 8 cutting direction.

They extend the benefits of laser cutting to a whole new range of materials.

It works on the principle of flying optics.

This construction type allows extremely high acceleration values.

What is a fiber laser cutter.

With power ranges from 4 to 6kw the m series is a highly productive system for a variety of applications.

With an innovative motion system and advanced structural design the lcg aj series represents an optimal balance.