The cpi sl2000 6000 is the first linear position sensor of its type in the world capable of subsea operation in any hydraulic cylinder or accumulator greater than 8 inches in diameter.

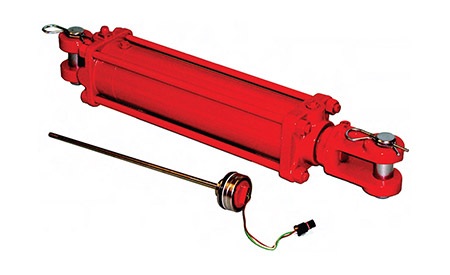

External hydraulic cylinder position sensor.

They are exceptionally well suited for use in hydraulic cylinders for position feedback for molding and rolling mills or for elevator and hoisting technology.

Magnetostrictive variable resistance and variable.

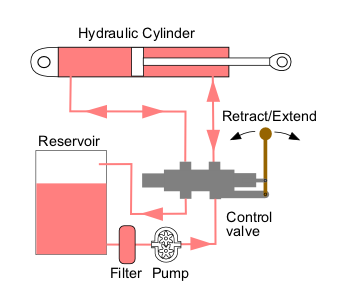

Mechanical motion systems.

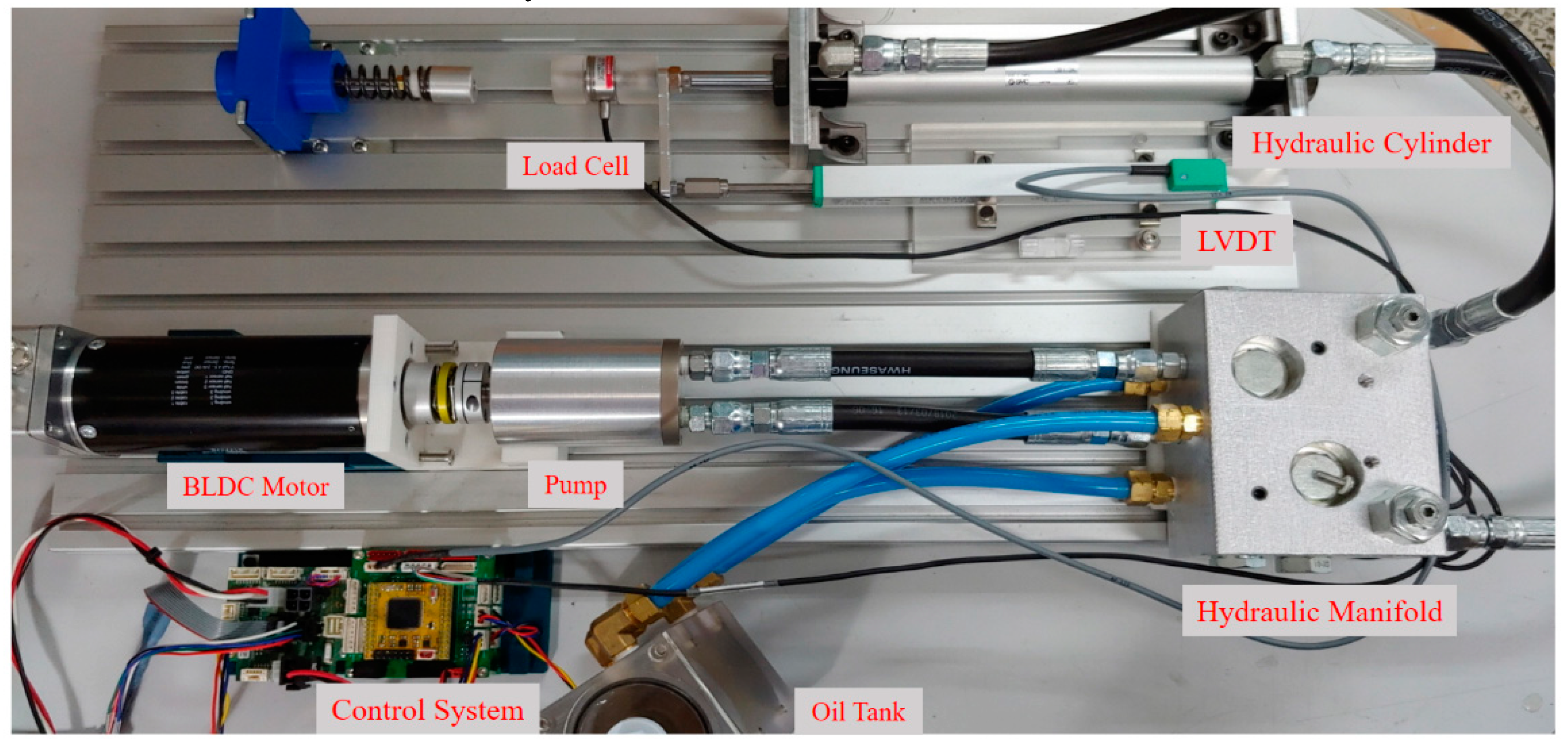

As the demand for increased control and functionality has increased over the years sensor instrumented.

Bulletin 871d cylinder position sensors are ideal for end of stroke detection on hydraulic and pneumatic cylinders.

The siko position sensors of the sgh range profit from more than 30 years of development experience in wire actuated encoder technology.

Populating these cylinders are position feedback sensors which employ one of three traditional technologies.

Special spacers are available to alter the probe length for specific applications.

The cable connector installs into the piston or rod via a 7 16 20 threaded connector and the sensor is coupled to the cylinder via a hydraulic hose through a.

External linear displacement transducers ldts eliminate the need for a hollow hydraulic cylinder rod.

A hydraulic port on the end cap provides continue reading external position feedback for hydraulic.

The magnet propagates a magnetic field through the steel wall of the.

Internal external linear transducers radial transducers and position switches often used with hydraulic cylinders rota transducers are used throughout the world in some of the harshest environments in the oil and gas industries both subsea and topside in the tunnelling mining construction and agricultural industries where they are.

This is accomplished by the placement of a permanent magnet within the piston.

Cpi s hydraulic cylinder position sensors install into standard hydraulic cylinders with minimal modifications and are suitable for field retrofit where rod type sensors have failed.

Optional signal conditioning electronics could be mounted outside the cap end at left.

Each sensor mounts into the standard in port cylinder position sensor bolt pattern.

Instead an external sensing bar utilizing hall effect technology senses the position of the hydraulic cylinder s piston.

This cross sectional view shows a hydraulic cylinder fitted with an internal position sensor.

The classic linear position feedback solution for hydraulic cylinders is the rod style magnetostrictive sensor installed from the back end of the cylinder.

The cylinder rod is gun drilled to accept the length of the sensor probe and a target magnet is installed on the face of the piston.

These sensors are also atex and iec ex intrinsic safety rated and support stroke lengths up to 30 meters.

.jpg)